7.5 Gauge bug

I was looking for something to change and still work with the trains, so I Jumped gauges from 1/87th to 7.5 gauge.

Click on any photo to enlarge the photo

So in comes 7.5 Gauge work shop.

The body of the switcher engine is cut on a plasma cutting table. Holes are drilled and screws are added.

The under frame of the switcher has to be cut out of different material and cut to size. The side plates are then drilled out using a pattern to follow.

Sound boards are made up and ready to be installed on to the main power board. The motors are mounted on to a steel plate. Pillow blocks hold the chain tight on the shaft. Support bearings to hold the axle into place will be next with the wheels to follow.

The cabs are primed so they will not rust. This way they are ready for paint.

Mounting the wheels and motors to the frames. Hooked up two batteries to run the motors to test if they need any fine tuning.

Three are fully assembled and waiting for the main base to be put on.

The chassis is done and ready for the body to be installed.

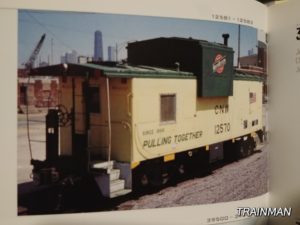

And if that isn’t enough. I went and started a caboose.

This is the caboose. I used a program to transfer the size and shape over to a CNC cutter.

Cleaned up the metal and primed the caboose.

Cleaned up the metal and primed the caboose.

Adjusted the sides and drilled out the holes to put together. Next is to make the inside supports.

O Let’s not forget the engine too.

The engine sits at the Virginia Transportation Museum. Did a program to make the cab of the engine.

Cut it out of 16 gauge 4’x8′ sheet steel. Talked to someone that had photo’s back in the 1980’s.

I took the front plate and started working on the radiator for the engine.

Got help from two other people. This is what the radiator will start as.

After much sanding on the radiator I think it looks great.

I have to put side panels on to hide the batteries. An engine that was two years newer had these doors.

Adding the lights was another task because of the size of the engine.

“O” Lets not forget the caboose.

Windows and door are finished. Just needs a coat of paint.

In April of 2019 the engine is needing the brakes on the side and the caboose needs the end platforms made.

Time to put more info on the story. I have been working on the engine to get the details done and is’t taken some time. The engine has been turned in to the NMRA to be judge. The score ended up at 109 out of 125 points.

It’s a shame you cant see the details on the sides so I added this photo.

The axle has a castle nut with a cotter pin in it. A tube for the sander on the left. Working brake assembly to the right of the wheel. Lets not forget the caboose.

Up dates to this story might take some time. Off to the track……

Final wiring on the engine.

OK It’s been a while and the Caboose has some decals on it.

Thanks for this.. are/were you making a production run???

What does it take to raise the score to perfect?? A higher degree of difficulty?? Maybe.. live steam mallot engine..?? Comparing apples and donuts..